OEM CE Certification Hardcover Case Making Manufacturer – QZFM-700/900 Automatic Case Making & Inner Laminating Machine – Horda

OEM CE Certification Hardcover Case Making Manufacturer – QZFM-700/900 Automatic Case Making & Inner Laminating Machine – Horda Detail:

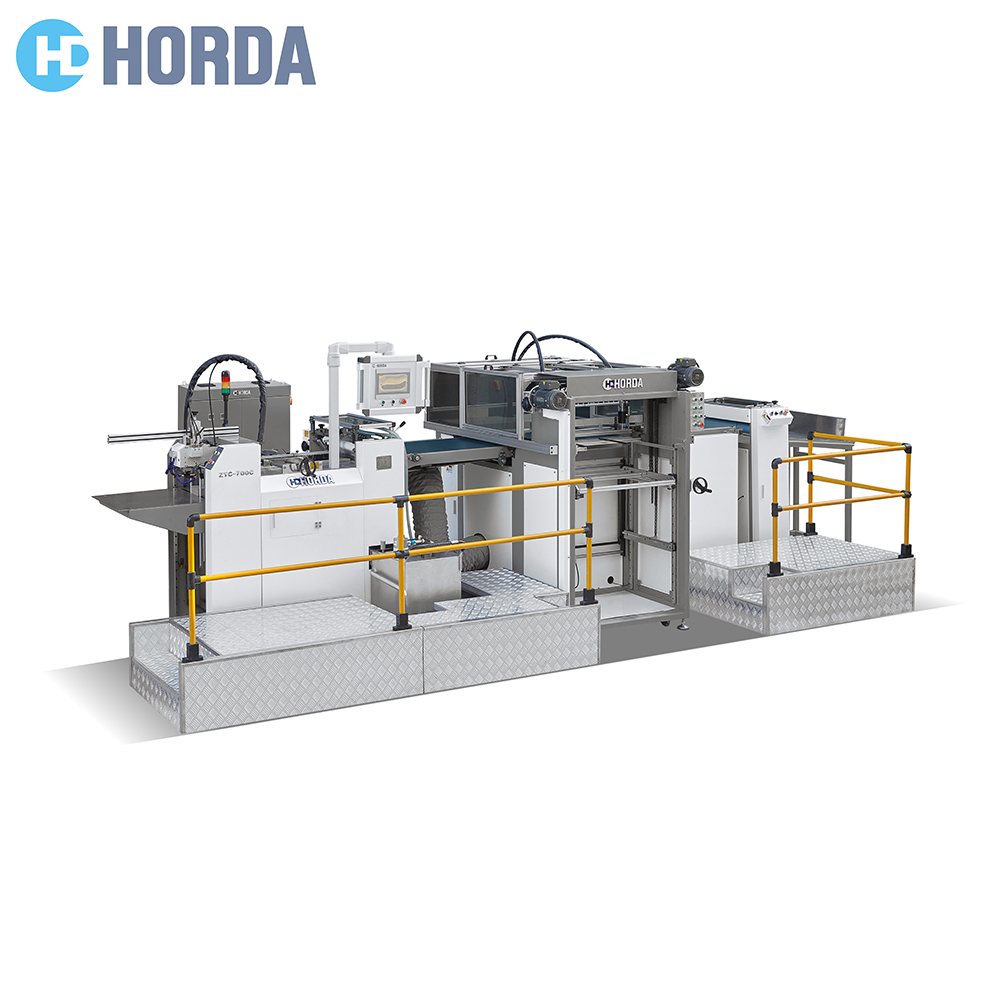

QZFM-700/900 Automatic Case Making & Inner Laminating Machine is one of our main products. Through the long term market survey and research, with years of experience in production of hardcover cover equipment, and combining the future developmental needs of domestic & foreign markets, we develop this fully-automatic production line, which can finish four-side folding and inner paper laminating at one time. This machine fills the market gap of multifunctional case maker, and satisfies customers’ requirement of high quality, high accuracy, high speed and low labor during production. It makes the development of hardcover equipment enter a new stage.

QZFM-700/900 Automatic Case Making & Inner Laminating Machine adopts PLC control, servo drive system, photo sensor detect system, servo correction positioning system as well as some of new technology. It integrates with many processes such as paper feeding, gluing, board feeding, photo sensor detecting, Servo positioning, flattening and folding. It can be applied for high volume packaging material production of moon cake, tea, cellphone, underwear, handcraft products, cosmetics, folder, calendar, hard cover books and so on. It provides the efficient production solution for those products.

The first enterprise in the industry to adopt professional feeder which is dedicated to printing machine . It makes adjustment convenient and fast, production in high speed, performance stable and reliable.It uses three sets of Germany LEUZE photoelectric

detecting systems which enables to control the positioning error range within ±0.2mm, and adopts four sets Japanese Panasonic servo motors which makes the maximum production speed 30 PCS/MIN.

Paper conveying structure with automatic constant temperature heating function to prevent roller sticking paper caused by water vapour Cardboard feeding mechanism applies Japanese Panasonic servo system, which is not only high precision, fast, but also reliable.Enhanced the board changing efficiency with the reasonable and humanized design.The mechanical edge folding technology is to complete the four-side folding in one plane, which reduces the scratches and make the product nice

and artistic.

A. Paper Feeder

The first enterprise in the industry to adopt professional feeder which is dedicated to printing machine. It makes adjustment convenient and fast, production in high speed, performance stable and reliable.

B. Gluing Unit

Paper conveying structure with automatic constant temperature heating function to prevent roller sticking paper caused by water vaper.

C. Board Feeding System

Cardboard feeding mechanism applies Japanese Panasonic servo system, which is not only high precision, fast, but also reliabl. Enhanced the board changing efficiency with the reasonable and humanized design.

D. Three Photoelectric Detection

It uses three sets of Germany LEUZE photoelectricdetecting systems which enables to control the positioning error range winthin ±0.2mm, and adopts four sets Japanese Panasonic servo motors which makes the maximum production speed 30 PCS/MIN.

E. Platform-based Folding System

The mechanical edge folding technology is to complete the four-side folding in one plane, whichreduces the scratches and make the product nice and artistic.

F. Collection

Automatic products collection system, reduces the labor greatly.

(Not standard with machine, please choose freely according to actual needs):

1.Viscosity controller Can automatically add water and keep it at a stable viscosity value, good help for user without experience of using case maker.

2.Cold glue(white glue) system Equipped with a glue pump especially for cold glue use, can satisfy customer’s requirements of making various products.

3.Bottom-suction device Used at inner lining process, fitting for the products with the cover material easily scratched, bottom suction device feeds the board from bottom, can 100% avoid the scratches on product surface.

4.Soft Spine device It’s specially designed for hardcover book manufacturers.The minimum spine thickness:≥ 250g, minimum width: 15mm.

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for OEM CE Certification Hardcover Case Making Manufacturer – QZFM-700/900 Automatic Case Making & Inner Laminating Machine – Horda , The product will supply to all over the world, such as: Macedonia, UK, Barbados, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!