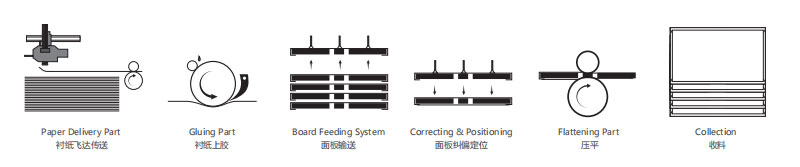

ZTC-700/1000/1350A Automatic Inner Paper Laminating Machine uses servo drive, photoelectric positioning, servo correction and other latest technology as well. This machine can automatically finish the inner paper feeding, gluing, cardboard feeding, positioning and pre-flattening processes with high accuracy, fast speed and highquality.Thus this machine is the preferred solution for printing and packaging enterprises to make the hardcover inner laminating process.Material of inside lining paper including writing paper, coated paper, specialty paper, synthetic paper, cloth etc.

The first enterprise to adopt professional feeder which is dedicated to printing machine in the industry. It enables adjustment convenient and fast, high speed production, performance stable and reliable.

The photoelectric detecting and servo correcting unit help the board laminating on the inner paper quickly and accurately.

The operating system with touch-screen can display the machine fault and hint directly which makes the operation more convenient as well as rapid troubleshooting.

Japan Panasonic PLC, Frequency converter

Japan Panasonic servo motor

Japan NSK Bearings

Japan ORION Vacuum Pump

German LEUCE photosensor

Taiwan Airtac Pneumatic Component

| Model | ZTC-700A | ZTC-1000A | ZTC-1350A | |

| Maximum size | mm | 450×720 | 600×1050 | 750×1350 |

| Minimum size | mm | 90×180 | 140×190 | 140×190 |

| Board thickness | mm | 1-3 | 7-3 | 7-3 |

| Paper weight | g | 105-210 | 105-210 | 105-210 |

| Maximum speed | Pieces/min | 20-30 | 15-25 | 10-25 |

| Positioning accuracy | mm | ±0.2 | ±0.5 | ±0.5 |

| Power supply | kw | 73.5 | 14.5 | 15 |

| Machine weight | kg | 2300 | 3000 | 3500 |

| Dimension (L×W×H) | mm | 6500×2600×1500 | 7800×3000×1500 | 8500×3000×1500 |