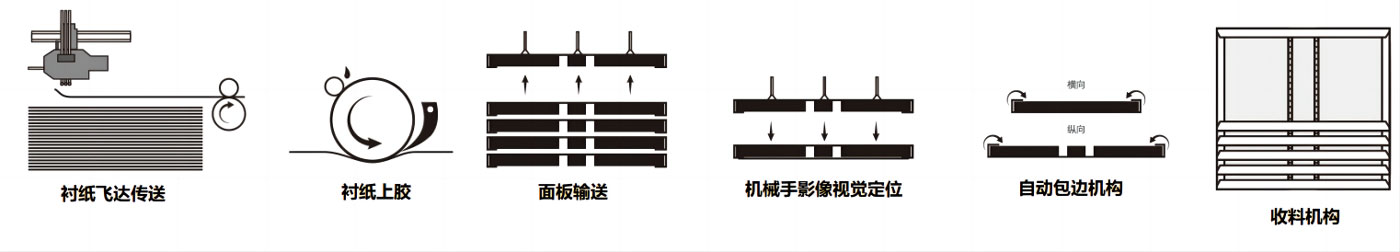

ZFM-500B Automatic Case Making Machine (CCD) adopts new technologies and processes such as special paper feeder, high-precision camera for accurate positioning, robot for fast board feeding, special mechanical structure for folding edges, etc. It can automatically complete the processes of paper feeding and gluing, board feeding positioning, corner folding, four-side folding, automatic paper collection, etc. The machine adopts motion control system, with the maximum production speed of 40 pieces/minute and the minimum finished product size of 120mm×60mm, filling the market gap of small hardcover box making machines.

The first enterprise to adopt professional feeder which is dedicated to printing machine in the industry. It enables adjustment convenient and fast, high speed production, machine performance stable and reliable.

Special mechanical folding structure enables edge-folding tighter and no scratches on surface.

It's equipped with high precision camera, makes the error of precision within ±0.1mm,which greatly meets the strict precision requirement to high-grade packing box.

It adopts motion control system,which responsed quickly with stable performance.The production speed can reach 30-40 pcs/min.

The machine is an entirely new designed prioritization scheme with compacter structure, and more convenient adjustment. The production efficiency will be improved greatly.

Japanese Panasonic Thermostat and Inverter

TRIO motion control System

ESTUN SCARA Robot

Hikvision Camera

ESTUN servo motor

Japanese NSK Bearings

Japanese ORION vacuum pump

Taiwan PMI linear

Japanese CKD pneumatic element

German LEUZE sensillum opticum

Taiwan AIRTAC pneumatic element

French Schneider Electric

| Model | ZFM-500B | |

| Maximum size | mm | 350mm×500mm |

| Minimum size | mm | 60mm×120mm |

| Board thickness | mm | 1.0~4.0mm |

| Paper thickness | g | 105~210g |

| Maximum speed | Pieces/min | 25-40 Pieces/min |

| Power supply | kw | 19KW |

| Machine weight | kg | 3500kg |

| Minimum spine width | mm | 8mm |

| Dimension (L×W×H) | mm | 5500×2500×1800mm |

| Positioning accuracy | mm | ≤+0.1mm |