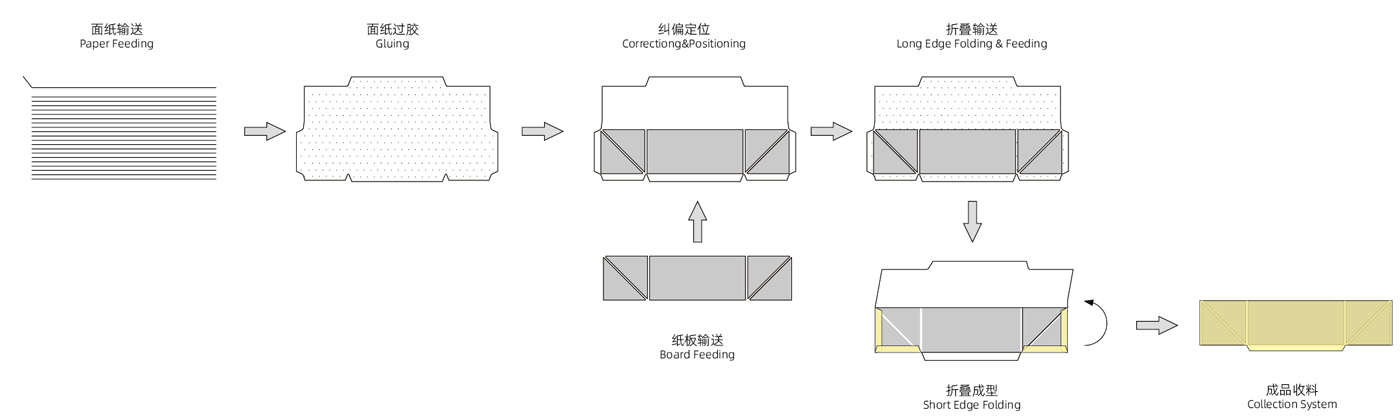

HORDA has cooperated with Zhejiang University to develop the ZDH-700K folding box-wing machine based on the actual needs of users. The whole machine uses 12 servo systems, which can accurately complete the actions required for each process, reducing the transportation volume of cartons by more than 80%, which not only greatly reduces transportation costs and storage space, but also has almost no damage or deformation.

4 photoelectricity Positioning is more accurate

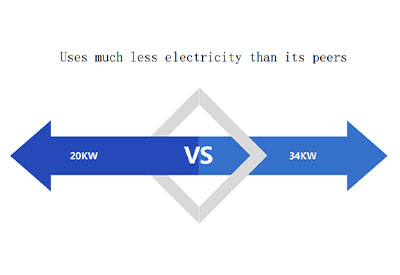

Uses much less electricity than its peers

Pressing Long Edge Function

Adopting the structure of clamping the grey board with the insert plate and pressing down, wrapping the edger more tightly.

secondary flattening

| Model | ZDH-700K | |

| Maximum size | mm | 180×700 |

| Minimum size | mm | 38×200 |

| Paper weight | g | 100-200 |

| Board thickness | mm | 1.0-3.0 |

| Side board thickness | mm | 0.5-2 |

| Speed | Pieces/min | 20-30 |

| Positioning accuraCy | mm | ±0.25 |

| Power supply | KW | 20 |

| Weight | kg | 3500 |

| Dimension | mm | 7400×2500×1500 |