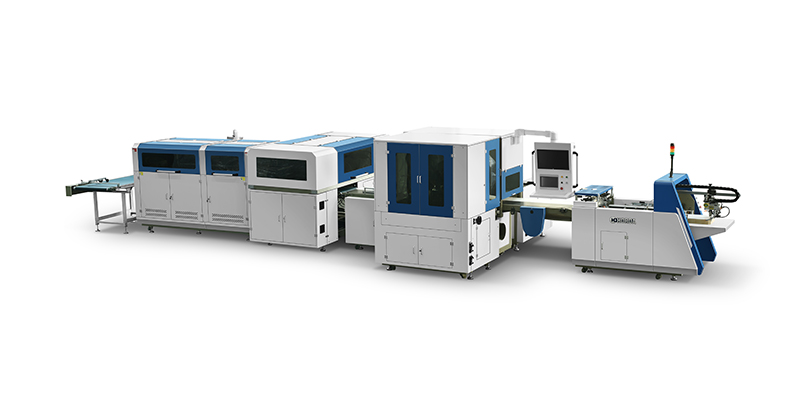

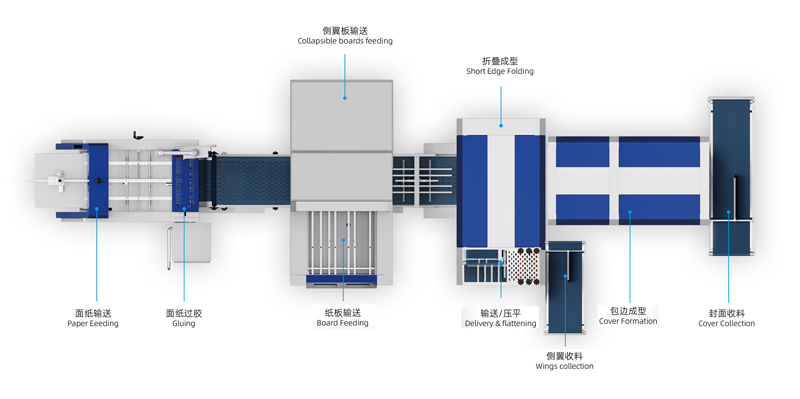

This machine is designed for small batch, high-end customized orders, integrating three functions: case making, collapsible box wings making and inner lamination. It supports fast mode switching and completes within 10 minutes after specification presetting, which improves the efficiency of size changing. It's equipped with 23 sets of servo motors, with dual manipulators & visual positioning system, stable and accurate operation; self-developed suction structure adapts to a wide range of materials, realizing flexible, intelligent and efficient packaging production.

4 photoelectricity Positioning is more accurate

Uses much less electricity than its peers

Pressing Long Edge Function

Adopting the structure of clamping the grey board with the insert plate and pressing down, wrapping the edger more tightly.

secondary flattening

| Model | DFM-1000B | |

| Maximum size | mm | 600x1050/180x700 |

| Minimum size | mm | 140x240/50x200 |

| Paper weight | g | 100-250 |

| Board thickness | mm | 1.0-3.0 |

| Side board thickness | mm | 0.5-2 |

| Speed | Pieces/min | 20-30 |

| Positioning accuracy | mm | ±0.2 |

| Power supply | KW | 18/20 |

| Weight | kg | 6000 |

| Dimension | mm | 12500x3700x1900/9400x3500x1900 |